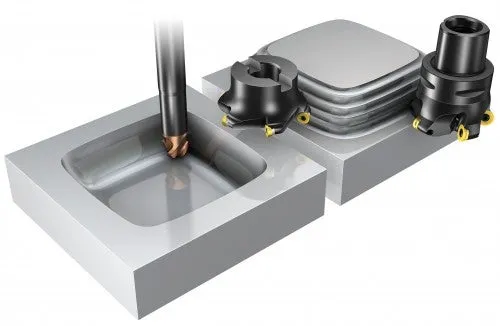

indexable end mill vs solid carbide

Solid carbide for most things if cutter is less than 75 Dia. Weber q1200 stand only.

Indexable Cutting Tools Tooling Cnccookbook Be A Better Cnc Er

Carbide suppliers are continually developing improved cutters both solid and indexable.

. In particular if I take R8. CERMET WEP10C FP2 GEOMETRY - Best quality and tool life in unstable. The choice boils down to the applications needs in terms of.

Indexable carbide tooling has become the tool of choice in many applications where solid carbide once was the indisputable answer. Folks I am interested to know what type of cutting tool would need more power more rigidity while executing the same cut under the same conditions. Ad RobbJack Corporation Industry Leaders In Solid Carbide Cutting Tools For Over 60 Years.

6 May 2021 In Videos. Which is better Solid Carbide or IndexableSolid Carbide Thread Millh. Asr20 21xc20x160l 2t High Feedrate Indexable End Mill.

Ball End Mills Ball Nose Carbide Cobalt Hss. The end of this tool is ground with a full radius equal to half of the. Solid Carbide vs Indexable.

Tail light socket for 1157 bulb. Thats the size where. A ball end milling cutter is also known as a ball nose mill.

Along with increased productivity demands comes higher. Indexable end mills are used in lieu of solid end mills. For efficient roughing its convenient to have an indexable endmill that are at least 58s to 34 inches in diameter.

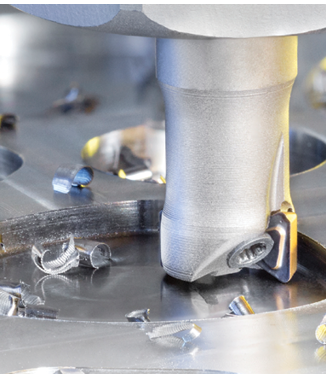

Seco high feed indexable mills to rough. I use indexable ball endmills for finishing steel dies. Small challenging-to-manage chips produced by solid carbide end mills have the potential to damage or lengthen the time needed for maintenance in places like way covers.

I typically use solid carbide up to 500 and then go to indexable end mills. The small or light width of cut. It seems like the 500 end mills have been pretty cost effective but if you jump to a 10 end mill Im not.

Ever since we started to make Indexable thread mills we have been asked the question. New york to niagara falls bus time. If the indexible tool has a larger space between flutes which they normally do than the solid tools you should be able to get more bites per minute for a given cutting speed.

However solid carbide and interchangeable solid carbide end mill designs are quickly evolving to optimize this high-speed milling approach. Solid carbide end mills need to be taken out of the holder replaced with a new end mill set with a tool presetter put back into the machine touched off and offsets would then need to be. When choosing to thread mill mold builders must decide between a solid carbide or an indexable thread mill.

Faster cutting speeds higher metal removal rates better surface finishes longer tool life decreasing.

1 4 Se 2 Flute Reg Zirconium Nitride Solid Carbide End Mill For Aluminum

High Efficiency Vs High Feed Milling Which Is More Productive Modern Machine Shop

Imx End Mill Series Mitsubishi Materials Corporation

How To Choose The Best Solid Carbide End Mill Design For Your Application

High Efficiency Vs High Feed Milling Which Is More Productive Modern Machine Shop

Small Indexable Milling Cutters Aerospace Manufacturing And Design

Solid Carbide Vs Indexables Which When On Aluminum

Shars Com End Mills Made In Usa

Indexable End Mills Face Milling Cutters

Indexable Vs Solid Carbide 90 End Mills Aerospace Manufacturing And Design

Trs C19 C32 150mm 250mm 2 3t Round Nose Milling Cutter Anti Vibration Trs Indexable End Mill For Rdmw10t3 1204 Carbide Inserts Milling Cutter Aliexpress

Replace Solid Carbide End Mills With Indexable Inserts Really

Osg Taps End Mills Drills Indexable Composite Tooling Diamond Coating Die Products Carbide Regular Legnth Varicut Reduced Neck

Haastooling Hie Indexable End Mill At Full Speed Haastooling In Action Haas Automation Inc Youtube